Blog 2

HOW TO CALCAULTE YOUR SLUDGE GENERATION AND HOW MUCH TO WASTE SLUDGE IN YOUR ETP or STP?

One of the commonly overlooked and neglected but one of the most critical aspects of a biological treatment process control is the sludge wasting control. This is most important process control step which helps the operator to maintain the SRT or the Sludge Retention Time and the F/M ratio (Food to microorganism ratio).

Why sludge wasting is important?

If we simply put it, sludge wasting maintains the right balance of food and microbial concentration which provides the optimum biokinetic (speed of reaction) environment for removal of organic pollutants while maintaining the right sludge settling properties.

Why are sludge settling properties important?

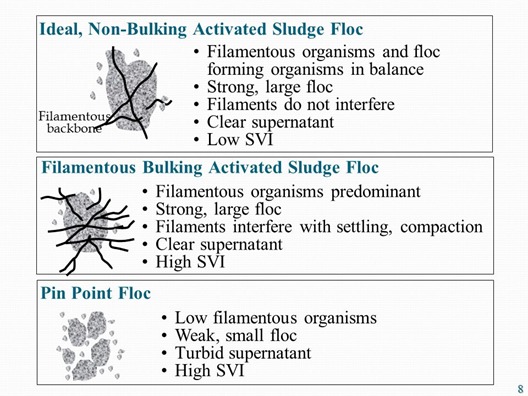

It has often been observed that the sludge settling is greatly affected by the sludge concentration and the type of sludge present in the secondary clarifier. By properly wasting the sludge an operator is able to maintain and ideal Sludge Volume Index (SVI) which is a proxy measurement for the settling property of the sludge. If the sludge does not settle properly and overflows, all the COD removed in the form of sludge escapes the system and the performance of the plant deteriorate- this is a condition where filamentous bacteria dominate; similar is the case when the sludge settles very quickly but the supernatant is quite turbid, which is a result of very long SRT and granular sludge. Thus, we can see that the sludge wasting has profound impact on the settling properties and ultimately the plant performance.

When to waste the sludge?

Now that we have understood the importance of the sludge wasting, we need to define when to waste sludge. Typically, even if a plant is designed at a certain sludge wasting, often the actual amount of sludge to be wasted depends on the actual running conditions of the plant like organic load and the biomass concentration developed. A very simple yet very practical and representative approach is the SVI test. SVI ranging from 90-120 is the ideal for an activated sludge process and in some cases for SBR type plants where more granularity of sludge is achieved the ideal SVI ca be lower upto 50-60. If the SVI > 120-150 the operator is required to waste the sludge.

SVI = 1000 X Settled Sludge Volume / (MLSS concentration)

How much to waste the sludge?

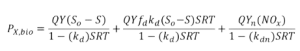

Generally, the equation which is used for estimating the sludge wasting is provided herewith

A good resource for the calculation of quantity of sludge generation can be accessed freely on following link. This not only give the ideal sludge wasting quantity required in terms of kg/day but also provides the F/M ratio calculation, so that the user can adjust the sludge wasting based on the SRT and his targets of effluent treatment.

BOOK REVIEW

Green Signals- by Jairam Ramesh

Reprinted from Oxford University Press book introduction

An ‘insider’s’ take on one of the most contemporary issues in Indian politics

The debate on whether to privilege economic growth over ecological security is passé. Environmental considerations must be at the heart of economic growth, especially for a country of 1.25 billion people destined to add another 400 million by the middle of the century. Green Signals chronicles the ‘1991 moment’ in India’s environmental decision-making, telling the story of how, for the first time, the doors of the environment ministry were opened to voices, hitherto unheard, into the policy-making process. It details efforts to change the way environment is viewed both by proponents of environmental security and those who prize economic growth at all costs.

Told from the perspective of a pivotal decision-maker, the book addresses the challenges involved in trying to ensure economic growth with ecological security. It takes us through India’s coming of age in the global environmental and climate change community to take on a leadership role that was progressive, proactive, and steeped in national interest.

This collection reveals the story of the author’s attempt at the highest levels of governance to introduce effective decision-making, a transparent and accountable administration and to make environmental concerns an essential component of a nation’s quest to accelerate economic growth and end the scourge of poverty and deprivation.

Highlights

- Chronicles a tumultuous 25 months in a three-decade history of the environment ministry

- Told from the pivotal decisionmaker’s vantage point

- Rich in sources— contains speaking orders on high-profile projects, notes and letters to the PM, ministerial colleagues, chief ministers and others

Excerpt from the book

High growth is an imperative. We cannot ignore the overriding essentiality of growth in creating jobs, in generating revenues for investing in health, education, and infrastructure. At the same time, managing environmental risks must be integral to the growth strategy. The reverse is also true—the need for higher economic growth must be integral to environmental protection. Ecological security in a framework that promotes economic growth is what the country is looking for. We cannot forget that poverty is both a cause and consequence of environmental degradation. To take-off and logically extend from the then finance minister, Manmohan Singh’s 1991 budget speech, “we cannot deforest our way to prosperity and we cannot pollute our way to prosperity.”

TECHNOLOGY REVIEW

HOW TO CHOOSE BETWEEN TECHNOLOGIES FOR YOUR SEWAGE TREATMENT?

A comparison between Extended Aeration/SBR/MBBR/MBR

(Author- Urv Patel, SWA Environmental Consultants & Engineers)

Often there is a confusion among users and engineers alike on which technology best suites them for their wastewater treatment. Particularly, this is a more profound question when it comes to deciding among the various biological treatment process regimes; whether it is SBR, MBBR, MBR or our good old Extended aeration (or a modified Activated Sludge Process). This article aims to help answer these questions and bust common myths surrounding these “technologies” which rather we could refer as processes.

In a nutshell, when we refer to any other these technologies, we are actually referring to a different form of the same process which is the active-

ated sludge process. We simplify how they

differ as follows:

Extended aeration or Modified Activated

Sludge Processes

Extended aeration as the name suggests refers

to the most common type of biological treatment process used for COD and nitrogen removal. It involves a aeration tank followed by a secondary clarifier which collect the sludge to be recycled and wasted as per the requirement.

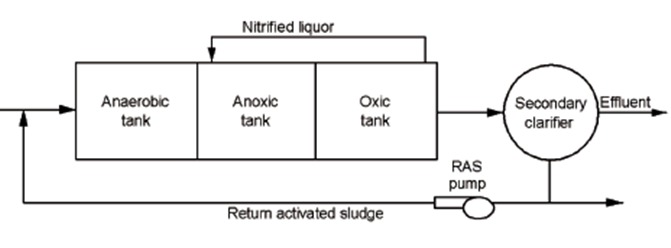

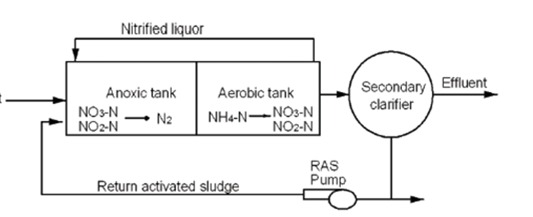

Sometimes, the configuration might change a little based on the COD strength, concentration of nutrients like ammoniacal nitrogen and phosphorous. Some of the variations are A20, AO, MLE process in which an anoxic tank and anaerobic tank is introduced to handle denitrification and biological phosphorus removal respectively. Anoxic tank is also sometimes recommended not just for denitrification but also as a metabolic selector for enhancing the settling properties of the sludge in clarifier. This process is very rugged and can be virtually used for any kind of wastewater,

Activated sludge process

Bardenpho process

A2O Process

AO process or Modified Ludzak Ettinger process

MBBR or Moving Bed Bio Reactor

This is the best process in 2 scenarios, one to upgrade the existing plant for 100% hydraulic load without constructing the extra tank or civil work (also higher organic load at the same hydraulic load) and the second is for high strength BOD loads more than 2000.

The economy in this is achieved by lowering of aeration tank volume requirement by providing plastic carrier which helps develop attached biofilm growth over and above the suspended biomass. The biofilm developed on carrier media results in higher microbial density and thus results in requirement of lower tank volume.

A typical MBBR media is provided is shown below:

Often, the MBBR media is used for also low strength organic wastewater like sewage where the COD is less than 500 mg/l, in this case it has often been observed that the addition or media does not offsets the tank volume requirement to justify the cost of media. Thus, it is recommend that for low strength wastewater like sewage, a conventional extended aeration be preferred, however, as discussed earlier there provides the best mode of retrofitting projects and plant capacity upgradation along with high strength COD wastewater where the saving in the tank volume is significant and the flux rate on biofilm is also higher.

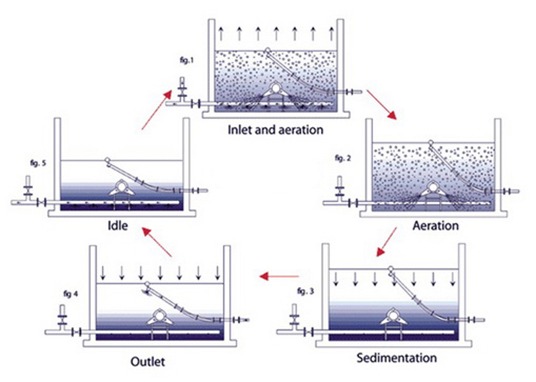

SBR or the Sequencing Batch Reactors

SBR has been the process of choice these days for sewage treatment projects because of the easily available PLC automation and process flexibility cum stability in operation. These are also provided a great advantage in large scale plants, by reducing area requirement. SBR process is characterized by a combination of tanks which are used for the aeration as well as settling. Due to the fast and feast conditions provided in the SBR basins the sludge is able to achieve granularity and this best settling properties. Although the SBR is the process of choice for large scale municipal projects starting from 1 MLD to 100 MLD + projects which are now up and running across India.

Nevertheless, for small scale plants <500-900 KLD the process is somewhat expensive as the decanter and the PLC automation required for the same results in higher costs compared to the conventional activated sludge process. Additionally, for small scall plants there is the question of high amplitude peaks in wastewater inflows which can create stability issues.

For industrial wastewater other drawbacks include complete reliance on PLC automation which can result in increased risk to process control in case of PLC failure. Decanter used for the same are proprietary and are expensive to replace. Thus, these can be preferred only for >1 MLD STPs. Nevertheless, there are many successful cases in industrial treatment as well, but they are exceptions and not the norm.

SBR or the Sequencing Batch Reactors

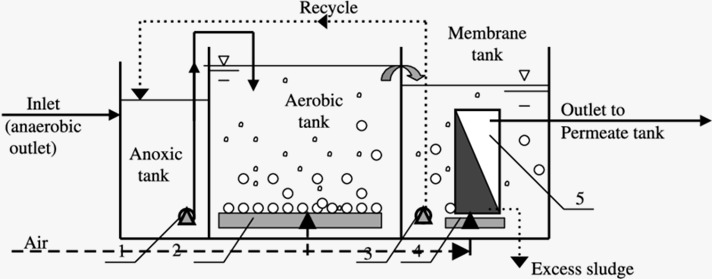

MBR or Membrane Bio Reactors

Membrane Bio Reactors or MBRs as the name suggests are the state of art latest addition to the activated sludge process category, characterized by a membrane instead of a secondary clarifier for the solid separation process. The membrane gives the most critical advantage of concentrating the biomass or the MLSS to the level of >8000-12000 mg/l. This enhance biomass concentration results in lower tank volume of the order of 3-5 times depending on the organic load.

This process is best suited where the area constraint is the most and the treated water quality requirement is very high i.e. <2-5 mg/l BOD and <1 mg/l TSS.

Some of the drawback include a higher concentration of filamentous bacteria can occur during the time of low flow and low organic load conditions, as the system operates on a extremely low F/M ratio during these period, this can increase its transmembrane pressures and ultimately the membrane cost. Another aspect to keep in mind is the high quality of the primary treatment or the screening <1 mm preferable for preventing any damage to the membranes becomes quire critical. Lastly, the membrane cost itself which need to be replaced every 3-5 years adding to substantial recurring capex cost.